During the SENSOR+TEST exhibition at the Nuremberg Exhibition Center from 10 to 12 May, 2022.

EDI scientists represented two solutions: IoT solution to monitor freshly poured concrete curing processes in real-time and contactless ice thickness measurement device.

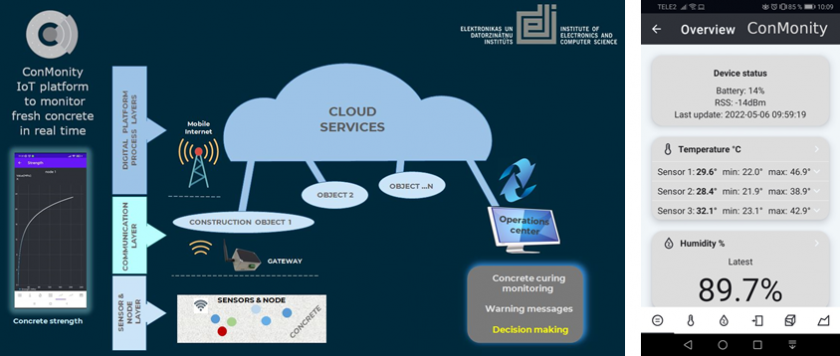

IoT solution to monitor freshly poured concrete curing processes in real-time.

The researchers of the EDI scientific institute developed IoT system “ConMonity” that receives all necessary concrete curing information from sensors (temperature, humidity, and three-dimensional stress) that are embedded into fresh concrete. Sensors cables are connected to wireless microprocessor controled datalogger that is the part of two tier communications network.

A construction company can monitor the concrete curing process on several construction sites simultaneously from its headquarters or via Android devices and make decisions. There is no need to travel to the sites to inspect the condition of freshly poured concrete.

ConMonity website: https://conmonity.edi.lv/

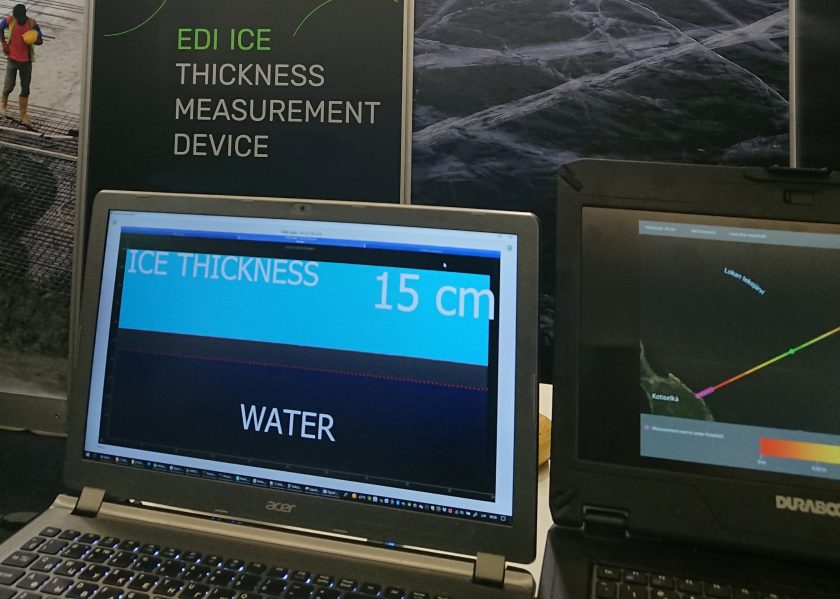

The other solution is contactless ice thickness measurement device with a display, but ice thickness data could be send to a remote server

There is a remote ice-thickness measurement method applied and the device is transmitting electromagnetic field (UWB) signals and receiving echo signals. Basically to measure the tickness of an ice there are two methods – contactless and contact.

Visitors of SENSOR + TEST exhibition could see two versions: one is portable hand-held device, the other can be mounted on a boat or small vehicle. The vehicle with mounted ice mesaurement device can go on the ice at speed up to 50 km/h and the ice thickness is measured.