Name of the project: Project „3D shape sensing fabric” (Project acronym – 3D FABRIC)

Aim of the project: is to develop the special strip of interconnected sensors (magnetometers, accelerometers, gyroscopes, etc.) for continuous monitoring of the deformations of the engineering constructions. The project aims to develop the technology for the technology readiness level TRL6.

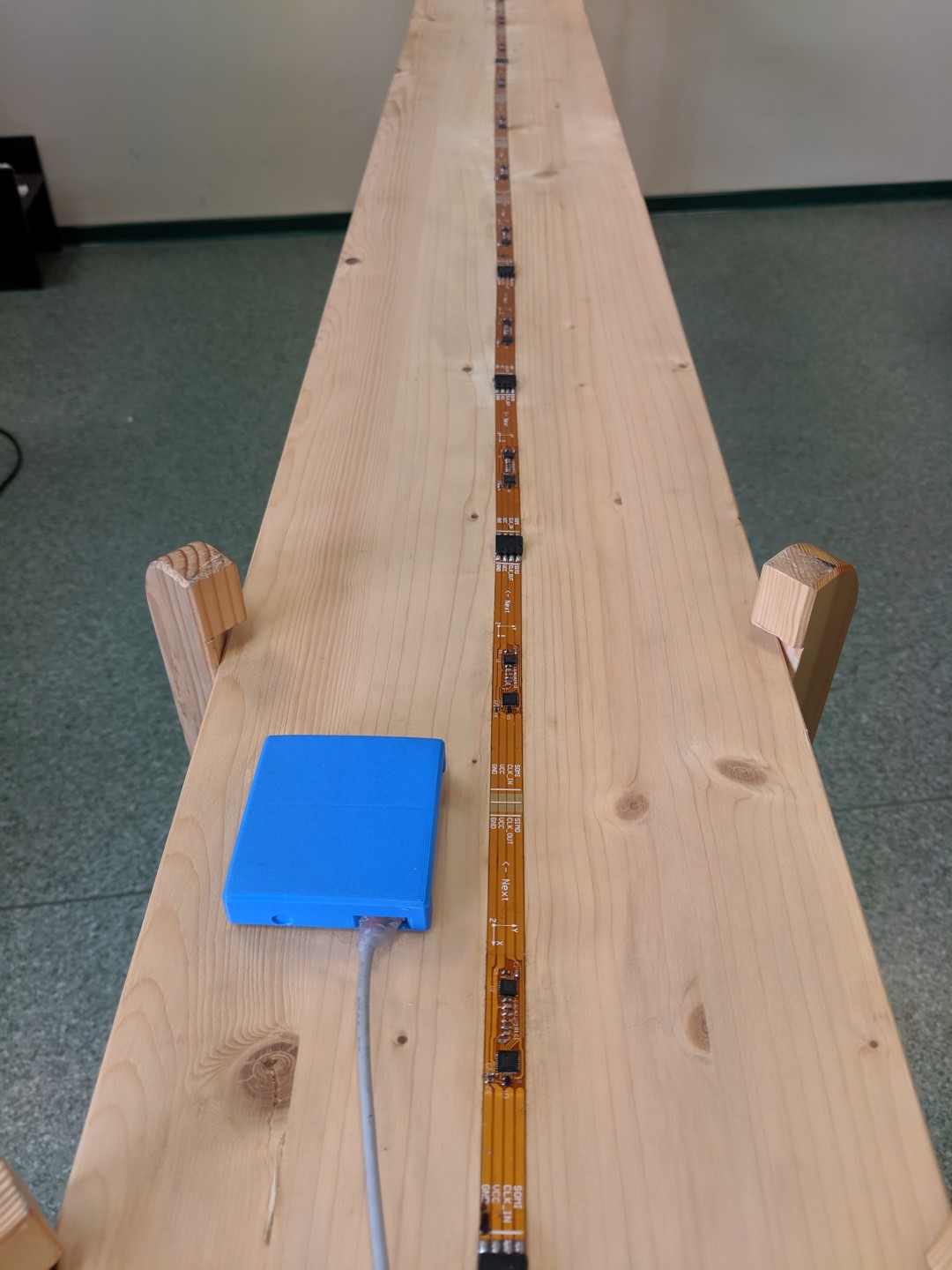

Developed technologies: The EDI research team has implemented the 3D surface shape-sensing technology in specially manufactured sensor strip which can be inseparably embedded into the constructions of the building or engineering structure. The sensor strip is connected to the data registration module and continuously provides data about the condition of relevant constructions (vibrations, irreversible movements, etc.). The technology can be used for various solutions, where the sensor strip is placed on the relevant object to read the data about the deformation or angular changes thereof. The technology can be used in industries where detection of deformation is a key, e.g., in carrying out engineering supervision over industrial engineering structures such as bridges, dams, high-rise buildings, and complex constructions.

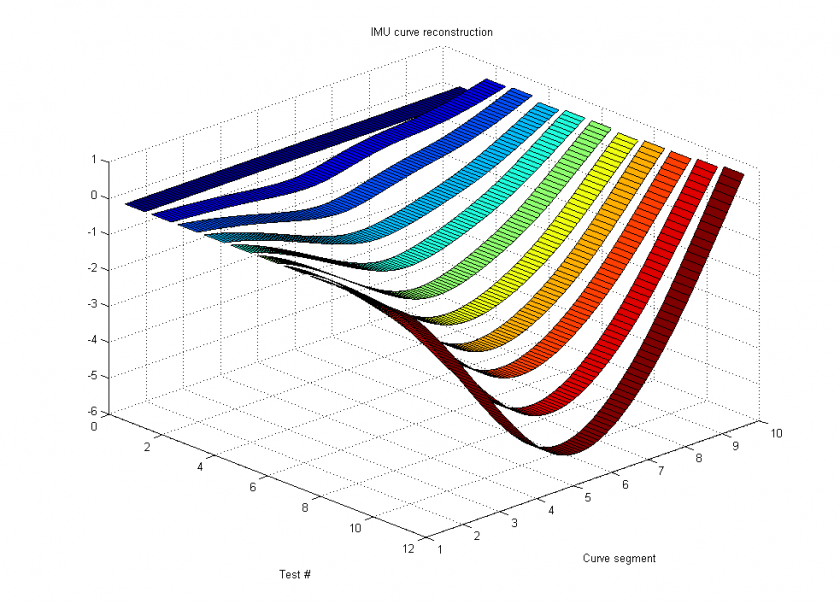

The 3D technology includes an efficient solution for sensor wiring that allows to connect up to several hundreds of sensors, ensuring high surface reconstruction accuracy. As for computing resources, the technology includes efficient surface reconstruction algorithms enabling surface reconstruction on small computing resource devices (such as smartphones, tablet PCs, etc.) in real time (updates up to 50 times per second).

The 3D technology is an innovative technology, because the difference of EDI technology from other technologies lies in its ability to efficiently connect a lot of sensors in a strip, as well as the option to complement the 3D surface reconstruction sensors with the sensors of other kind, which can be used to detect such aspects as air temperature or the temperature of the object, pressure, moisture, light intensity, etc.

Results achieved: Developed system can monitor engineering structure deformations in real time. Video: