In the field of smart production, EDI performs research and development activities (and offers expertise) in two sub-directions:

- sensor technologies (sensing, data acquisition, fusion, processing, edge computing, wireless transmission, etc.) to increase the performance of different robotic and mechatronic systems (incl. legacy systems, production lines, etc.);

- artificial intelligence and robotics technologies (e.g. AI-based detection, recognition, classification, and pick-up by a robotic arm).

For example, EDI has developed a low latency (<500us) real-time wireless sensor (Industrial IoT (I-IoT) device) with wireless charging capabilities, measuring key parameters of the system. Configuration allows changing the accuracy, frequency, and type of data measured, as well as adjust the radio transmission modulation, speed, and latency. Remote monitoring allows checking battery level, wireless charging speed/efficiency, and quality of radio transmission. The developed digital twin for wireless communication allows configuring the network in the simulation environment and transfer config files directly to the devices.

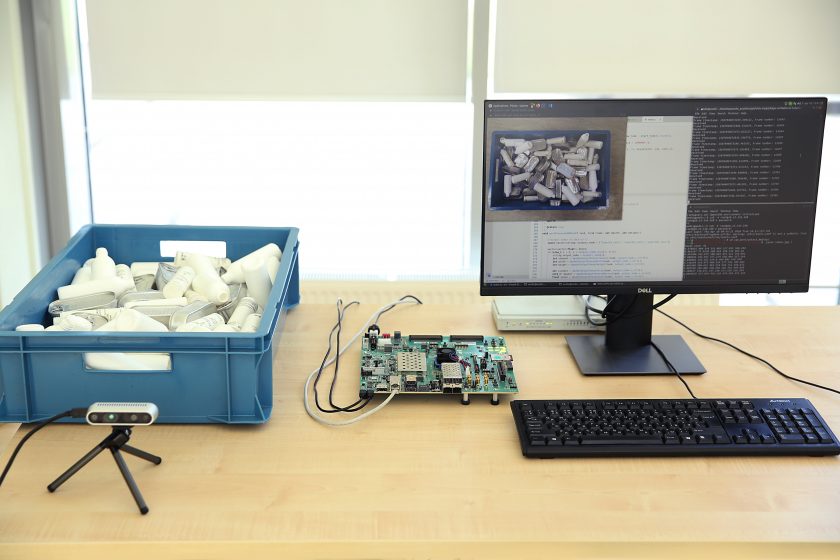

Another example is an adaptive robotic system that can recognize and sort various randomly placed objects from a box (or production line) using various sensors, computer vision, and deep learning. Such an intelligence-enabled robotic arm is able to adapt to unexpected situations in today’s dynamic manufacturing environment. We design CNN-based models and their training SW for detection, recognition, and classification of chaotically stacked objects (incl. plastic waste), implement stereo vision and ML algorithms on FPGA-based SoC (or GPUs) as Edge platform and implement a robot control system using ROS. In the field of AI, EDI has expertise in Automatic data generation/labelling methods, Machine Learning (ML) / Deep Learning (DL), Supervised (Convolutional neural network (CNN), Recurrent neural network (RNN), LSTM), Unsupervised (e.g. Variational), Generative adversarial networks (GAN), Transparent/explainable AI, Embedded intelligence (AI implementation in embedded systems

(FPGA, SoC, GPU, etc.)).

Yet, another example is related to silicon crystal growing, where EDI automated the process of silicon crystal growing by developing computer vision-based algorithms, control system as well as GUI to increase the performance of a legacy system and reducing the stability of the crystal diameter from 40mm to 4mm while replacing manual human work.

For many more examples and possibilities to apply our knowledge to your needs, please, contact us directly.